3003-H14 Aluminum Sheet

Excellent weldability, formability, with good corrosion resistance make 3003 Aluminum Sheet a popular and economical choice. 3003 Aluminum Sheet has a smooth, semi-shiny finish and is popular for many applications, including: fuel tanks, food & chemical handling, trailer siding & roofing, etc.

Non-magnetic, Brinell = 40, Tensile = 22,000, Yield = 21,000 (+/-)

5052-H32 Aluminum Sheet

Superior corrosion resistance, good weldability, with excellent formability, makes 5052 Aluminum Sheet a common choice for chemical, marine or saltwater applications. 5052 Aluminum Sheet applications include: tanks, marine hardware, boat hulls, etc. Non-magnetic, Brinell = 60, Tensile = 33,000, Yield = 28,000 (+/-)

6061 Aluminum Sheet

6061 T6 Aluminum Sheet is an aluminum sheet product that is very versatile and has a wide range of applications. 6061 Aluminum sheet is made from one of the most widely used heat treatable aluminum alloys. This sheet has excellent corrosion resistance, good workability and good machinability. 6061 sheet applications include a wide variety of products from medical assemblies, aircraft construction to structural components.

3003 Aluminum Tread Brite Plate

Aluminum Treadplate is commonly known as Diamondplate. It is strong, lightweight and is used to provide protection and traction on high traffic areas. 3003 Aluminum Tread Brite Plate has a raised pattern, which gives it its ‘diamond plate’ nickname.

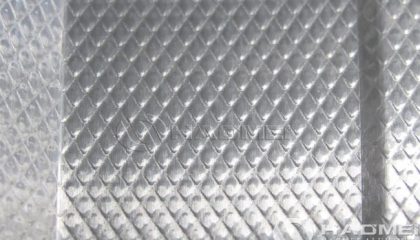

Rhombus Embossed Aluminum Sheet

Rhombus pattern embossed aluminum sheet is an aluminum alloy sheet with an embossed surface, usually with a rhombus or diamond pattern of concave and convex texture.

Diamond Aluminum Plate

Diamond aluminum plate are pressed bearing a raised diamond pattern on one side.

Aluminium Checker Plate

Aluminium checker plate is most commonly in alloys 5052, 3003, 1060 and 6061.

Aluminum Tread Plate

Haomei aluminum tread plate is durable and corrosion-resistant.Contact Us

Welcome friends from all over the world. We are always here waiting for your consultation.

- 1103 No.14 Shangwu Outer Ring Rd, New District, Zhengzhou, China.

- 86-371-65621391

- nydia@aluminumhm.com

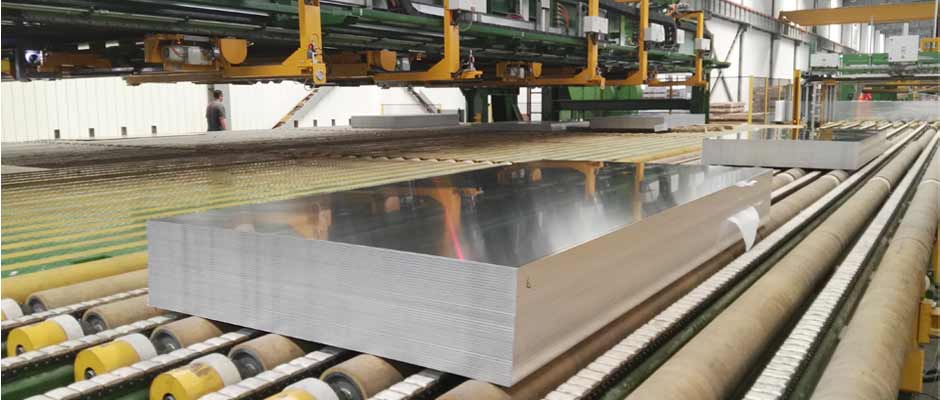

Aluminum Sheet

We have what you’re looking for in Aluminum Sheet. If you need Aluminum Sheet such as 3003 Sheet, 5052 Sheet and 6061 Sheet, we’ve got you covered,we can provide qualified products to you. In addition,we have various series of Aluminum Sheet from 1050-8011. Save time and money when shopping www.aluminumsheet.net with our speedy navigation, commitment to best pricing and best service on the internet.

The classification of the aluminum sheet

-

1Brushed Aluminum SheetIt is produced by using abrasive paper repeatedly to scrape lines on aluminum sheet. The main technological process can be divided into three pats: degrease,sander and washing. In the process of scraping lines of aluminum sheet,the special skin membrane technology after anodization can make the aluminum sheet surface generated a epithelial layer contained the metal elements,each tiny silk mark is visible,it makes the metal radiant fine-hair gloss.

-

2Oxidized Aluminum SheetPlace the aluminum sheet placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as anode, electrolysis the aluminum sheet in the effect of certain conditions and impressed current,then it is the oxidized aluminum sheet. Anodic aluminum is oxidized to form aluminum oxide thin layer on the surface, the thickness is 5 ~ 20 microns, hard anodic oxidation film can be 60 to 200 microns.

-

3PS Aluminum SheetNamely it is the aluminum sheet with printed pattern on the back and thickness of 025 or 03 millimetre.

-

4Mirror Aluminum SheetIt refers to the aluminum sheet processed by rolling, polishing and other methods to make its surface appear like a mirror.

-

5Embossed Aluminum SheetIt is a kind of aluminum product which form a variety of decorative pattern on the surface after rolling process on the basis of the aluminum sheet, it is widely used, mainly in packing, building, curtain wall, etc.

-

6Color Coated Aluminum SheetColor coated aluminum sheet has advantages as light weight, beautiful appearance and good anti-corrosion performance, and can be directly processed, save energy and prevent pollution.

Welcome to inquire the aluminum sheet information you want to us!

As a professional in the aluminum sheet export industry for 15 years, Haomei Aluminum consistently empowers global clients with accurate price analysis and solid product strength. Today, we combine the latest market data for 2026, practical experience, and industry insights to comprehensively analyze the price per ton of 7075 aluminum sheet, helping you avoid procurement pitfalls,.. read more →

As a sales representative at Haomei Aluminum, I have been deeply involved in the aluminum sheet export industry for many years, interacting with buyers worldwide with diverse needs. Inquiries about the 7000 series aluminum sheet price have consistently been a focus. Unlike conventional aluminum sheets, the 7000 series, as an ultra-high-strength aluminum alloy, has a price.. read more →