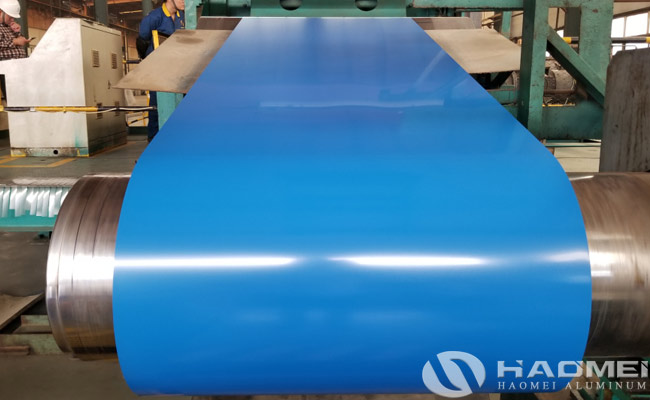

Roof aluminium sheet are Aluminum-Magnesium-Manganese alloy 3003 3004 special used for metal roofing, the thickness is 0.5mm-1.2mm. Usually, the 3003 and 3004 aluminium roofing sheet are coated with PE and PVDF coating to have beautiful appearance and long service life. After color coated, the aluminium roofing sheet system can withstand corrosion and sunshine, and the active life can be as long as 25 years without fade.

Aluminum, magnesium and manganese roof sheet, as its name implies, are made of alloys of aluminium, magnesium and manganese. Aluminum is light in weight and not easy to oxidize. Magnesium is soft in nature. Manganese metal has good corrosion resistance and toughness. The aluminum roofing sheet made of the three alloys have the characteristics of light weight, corrosion resistance and strong plasticity. There are 3003 and 3004 aluminum sheet metal commonly used in Al-Mg-Mn alloy plates. The essential difference between 3003 aluminum roofing sheet and 3004 aluminum roofing sheet is that the content of magnesium and manganese is different. The 3003 aluminum alloy is harder, while the 3004 aluminium alloy is softer, and the price of 3004 aluminum alloy is more expensive.

Aluminum, magnesium and manganese roof aluminium sheet are directly exposed to the air. Considering the factors such as wind resistance, stress strength and anti-corrosion, the selected aluminum sheet alloy requires strict processing. The exterior decoration of the roof system not only has good waterproof and thermal insulation performance, but also has a smooth and smooth appearance.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form