Aluminum sheet manufacturers in china have obvious advantages in terms of scale, technology, industrial chain, geographic location, policy and market demand, which makes Chinese aluminum sheet manufacturers highly competitive in the global market. China has a large number of aluminum sheet suppliers, many of which have advanced production lines and large-scale production capacity. This enables aluminum sheet manufacturers in China to meet the demands of domestic and international markets and offer competitive prices. China’s aluminum sheet suppliers are constantly introducing and developing new technologies to improve the performance and quality of aluminum sheets.

Many aluminum sheet manufacturers in china have professional R&D teams and technicians who can provide customized aluminum sheet products and solutions. China’s aluminum sheet industry has a complete industrial chain, including bauxite mining, alumina production, electrolytic aluminum production and aluminum sheet processing. This enables Chinese aluminum sheet supplier to better control cost and quality and improve overall competitiveness. China is located in the heart of Asia with convenient transportation, which facilitates the transportation and export of aluminum sheets. In addition, China has established trade relations with many countries and regions, providing favorable conditions for aluminum sheet exports.

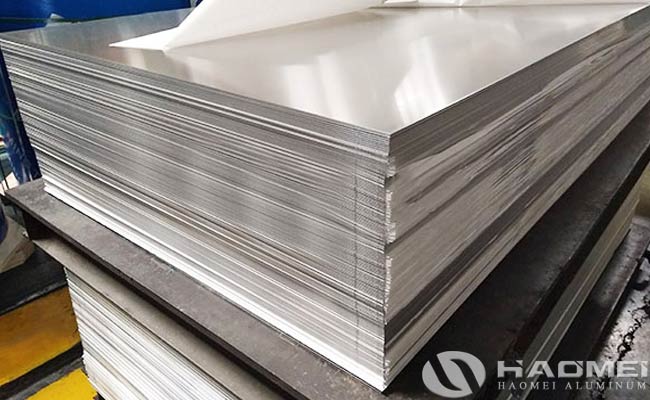

aluminum sheet manufacturers in china

Aluminum sheet manufacturers in china produce a wide range of aluminum sheet products to meet the needs of different industries and applications. Aluminum sheet manufacturers in China have a wide range of production equipment which is used for manufacturing, processing and surface treatment of aluminum sheets. Below are some common aluminum sheet production equipment:

Aluminum sheet production line:

This is a complete set of aluminum sheet manufacturing equipment that includes aluminum liquid storage tanks, aluminum liquid supply systems, casting machines, automatic cutting machines, and scrap recycling systems. The working principle of aluminum production line is to pass the heated aluminum liquid through the outlet of casting machine, with the help of directional refrigeration system to make the aluminum liquid quickly cooled into a certain thickness of aluminum plate.

Aluminum sheet rolling machine:

It is used to roll aluminum ingots into aluminum sheets of required thickness. This equipment is usually highly accurate and efficient, and can produce high quality aluminum sheet.

Cutting equipment:

Includes manual and automatic cutting machines that are used to cut aluminum sheets to the desired size. These machines can accurately cut aluminum sheets for a variety of applications.

Surface treatment equipment:

Used to apply surface treatments to aluminum sheets, such as anodizing, sandblasting, polishing, and painting. These treatments improve the corrosion resistance, aesthetics, and functionality of aluminum panels.

Forming equipment:

Such as bending machines, punching machines, etc., are used to process aluminum sheets into various shapes, such as arcs, bends, and bumps. These equipments can realize the complex processing needs of aluminum sheets.

Inspection equipment:

Including thickness gauges, hardness testers, metallurgical microscopes, etc., which are used to inspect the quality and performance of aluminum sheets.

Please note that the specific equipment configuration may vary depending on the size, technology and production needs of the aluminum sheet manufacturers in china. The above are just some common examples of aluminum sheet production equipment.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form