In the pursuit of energy-efficient and environmentally sustainable development, corrugated aluminum jacketing, as a new type of material that combines heat preservation, thermal insulation and corrosion resistance, are gradually demonstrating their unique charm in a variety of fields such as construction, chemical industry and food. In this article, we will discuss in depth the product specifications, characteristics and specific applications of corrugated aluminum jacketing for thermal insulation, and bring you a glimpse of the infinite possibilities of this innovative material.

Corrugated aluminum jacketing offer a wealth of choices in terms of specifications to meet the needs of different industries and application scenarios. In terms of alloy tempers, common grades include 1060, 1100, 3003, 5005 aluminum alloy etc. These aluminum alloys not only have good corrosion resistance and plasticity, but also high strength and stability. Thicknesses of aluminum corrugated jacketing range from 0.3mm to 1.5mm and can be selected according to specific insulation requirements. The width is from 1000mm to 1600mm, which is suitable for the construction of large-scale thermal insulation projects. In addition, corrugated aluminum jacketing can also be customized to specific lengths and shapes according to customer needs, to achieve precise matching.

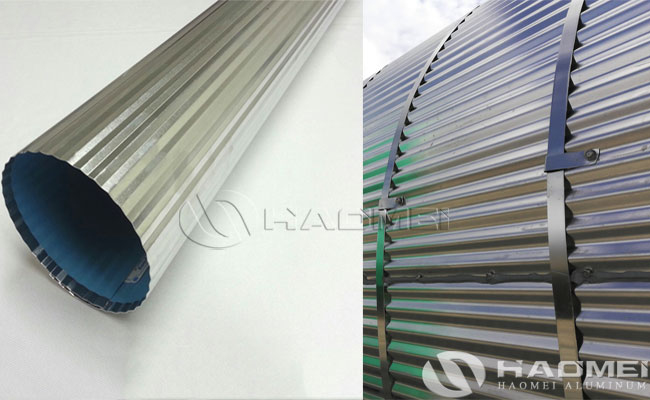

Corrugated aluminum jacketing are highly sought after because of their excellent thermal insulation and corrosion resistance. Its unique corrugated structural design effectively increases the surface area of the material and improves thermal resistance, making it difficult for heat to penetrate, thus realizing excellent thermal insulation. At the same time, the surface of the aluminum jacketing is specially treated, such as spraying, embossing or laminating (kraft paper, polysurlyn film), etc., which not only enhances the aesthetics, but also greatly improves the corrosion resistance, moisture barrier, and can be used for a long time without damage in harsh environments.

Corrugated aluminum jacketing has an extremely wide range of applications, covering almost all areas that require thermal insulation. In the construction field, it is often used as a thermal insulation layer for walls and roofs, which effectively improves the energy-saving effect and living comfort of buildings. In the chemical and pharmaceutical industries, corrugated aluminum jacketing are widely used in the thermal insulation and anti-corrosion of pipelines, storage tanks and other equipment to ensure the safety and stability of the production process. In addition, in the food industry, its good corrosion resistance and hygienic properties make it one of the most important choices for packaging materials.

To sum up, corrugated aluminum jacketing have shown strong application potential in many fields with their diverse specifications, excellent thermal insulation properties and corrosion resistance. With the advancement of science and technology and the continuous expansion of the market, we believe that corrugated aluminum jacketing will play an important role in more fields, contributing more to energy conservation, emission reduction and environmentally sustainable development. For industries seeking efficient and environmentally friendly thermal insulation materials, corrugated aluminum jacketing is undoubtedly a high-quality option that deserves in-depth understanding and exploration.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form