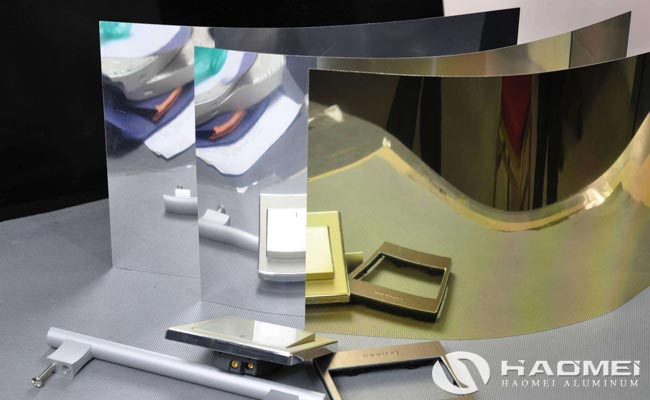

Mirror polished anodized aluminum sheet refers to the anodized aluminum sheet with mirror effect on the surface. This kind of aluminum sheet product has mirror effect after grinding, polishing, rolling extension and other processes, and its surface is smooth and flat with high gloss. Then the surface anodized treatment can improve the scratch resistance and weather resistance of aluminum sheet. Mirror anodized aluminum sheet does not have the shortcomings of fragile mirror and difficult to clean, but also has the advantages of light weight, moisture-proof and fire-proof, self-cleaning, weather resistance, corrosion resistance, etc. It is a high-end practical metal decorative materials.

The manufacturing process of mirror polished anodized aluminum sheet product are:

– Raw material preparation: choose high quality aluminum as raw material. Usually use 3003, 5052 and other aluminum alloy materials as the base material.

– Surface pretreatment: degreasing, washing and other pretreatment of aluminum sheet to remove surface grease and dirt.

– Mirror surface processing: through mechanical polishing, electrolytic polishing and other processes, the surface of aluminum sheet to achieve a mirror effect.

– Anodic oxidation: The mirror aluminum sheet is placed in electrolytic solution and electrolyzed as anode to form a thin layer of aluminum oxide.

– Post-treatment: The mirror anodized aluminum sheet is treated with dyeing, sealing, etc. to improve its decorative and durability.

The performance advantages of mirror polished anodized aluminum sheet are:

– High hardness: after anodic oxidation treatment, the hardness of mirror anodized aluminum sheet is significantly improved, and the wear resistance is enhanced.

– Corrosion resistance: the thin layer of aluminum oxide has excellent corrosion resistance and can resist the erosion of various chemical substances.

– High temperature resistance: the melting point of hard anodic oxide film is as high as 2320K, which makes the mirror anodized aluminum plate remain stable under high temperature environment.

– Strong decorative: the mirror effect makes the surface of aluminum sheet with high gloss and strong metallic texture, which is highly decorative.

Application fields of mirror polished anodized aluminum sheet are:

– Architectural decoration: Mirror anodized aluminum sheet can be used for architectural curtain walls, roofs, indoor and outdoor finishes, etc., to improve the aesthetics and grade of the building.

– Home decoration: as wall decorations, furniture accessories, etc., it can improve the beauty and grade of home space.

– Electronic products: Mirror anodized aluminum sheet has excellent conductivity and heat insulation properties, and can be applied to the shell of electronic products and heat sinks and other components.

– Automobile industry: It is used in automobile shells and body parts, etc. It has the advantages of rust prevention, weight reduction and vehicle performance improvement.

To sum up, with its unique mirror effect, excellent performance and wide range of applications, mirror polished anodized aluminum sheet has become an important member of the high-end decorative materials market.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form