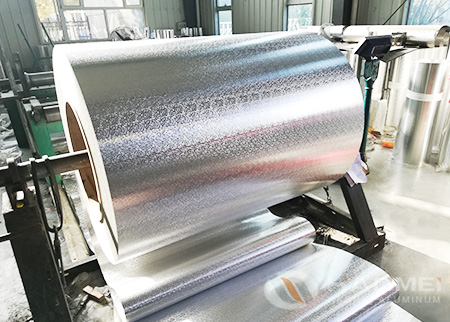

In the field of industrial and architectural insulation, aluminum stucco pipe insulation cladding has become one of the first choices for pipe insulation materials due to its unique performance and process advantages. Aluminum pipe cladding made after embossing treatment is widely used in pipe insulation and protection. Due to its light weight, high strength, corrosion resistance and good thermal insulation performance, stucco embossed aluminum pipe cladding is widely used in construction, petroleum, chemical, pharmaceutical and other industries.

First, the material and process: alloy and temper of the science of adaptation

Aluminum stucco pipe insulation cladding mostly uses 1000 series (pure aluminum) and 3000 series (aluminum-manganese alloy) aluminum alloy, for example:

– 1060 pure aluminum: purity of 99.6% or more, good ductility, suitable for pipe insulation in conventional environments, low cost and high processing efficiency.

– 3003 Aluminum-Manganese Alloy: Containing 1.0%-1.5% manganese, it significantly improves the rust prevention ability, suitable for pipeline projects in high humidity or coastal areas, and the corrosion resistance is enhanced by more than 30% compared with pure aluminum.

– 5052 Aluminum-Magnesium Alloy: In special corrosive environments (e.g. chemical pipelines), its magnesium content (2.2%-2.8%) enhances the resistance to chemical erosion and extends the service life.

– Processing tempers of stucco embossed aluminum cladding are commonly H24 (semi-hard state) or H14 (full hard state), the former balance of flexibility and strength, easy to bend on-site construction; the latter through the cold rolled to strengthen the hardness, suitable for outdoor pipelines that require high wind pressure.

Second, the technical parameters: thickness and pattern of the project to suit

Thickness selection:

– 0.5mm-0.8mm: mainstream thickness range, balanced lightweight (density of only 2.71g/cm³) and insulation layer protection needs, the weight per square meter compared to galvanized iron sheet reduced by more than 60%.

– Ultra-thin type below 0.3mm: suitable for small-diameter pipes or precision equipment insulation, need to cooperate with high-strength alloy (such as 5052) to avoid deformation.

Surface pattern design:

– Corrugated pattern: Enhance pressure resistance through wavy structure, suitable for pipes requiring frequent maintenance, reduce surface scratches during construction.

– Orange peel pattern: increasing the surface area to optimize the efficiency of heat dissipation.

Third, the core advantages of adaptable pipe insulation

– Light weight and construction convenience

Aluminum density is only 1/3 of steel, significantly reducing transportation and installation costs. Its high ductility (elongation up to 15%-25%) supports the wrapping of complex pipe shapes without additional cutting, increasing construction efficiency by more than 40%.

– Corrosion resistance and long life

Aluminum’s natural oxide film (Al₂O₃) can resist acid rain, salt spray and other erosion, with anodic oxidation or fluorocarbon spraying process (e.g., KYNAR-500 coating), the service life of up to 15-20 years, far more than the galvanized iron 5-8 years.

– Enhanced thermal insulation performance

The stucco embossed structure forms an air-insulating layer, which reduces heat conduction loss. Experiments show that pipes wrapped in 0.7mm thick aluminum cladding roll save 12%-18% energy compared to traditional materials.

– Environmental protection and economy

The recycling rate of aluminum pipe cladding is up to 70% with significant residual value, while the recycling value of iron skin is almost zero after corrosion. Long-term use can reduce the maintenance cost of enterprises by more than 50%.

With its superior performance and wide range of applications, aluminum stucco pipe insulation cladding has become an important choice of insulation material in modern industry and construction. With the enhancement of environmental awareness and the development of energy-saving technology, the market demand for stucco embossed aluminum cladding will continue to grow and will play a greater role in various fields in the future.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form