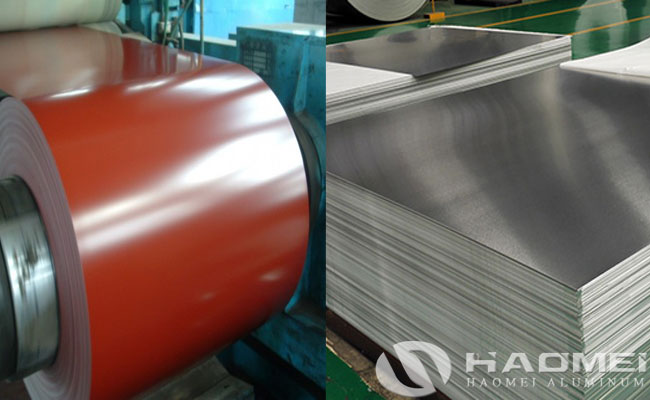

While used for outside roofing, the quality of china aluminum roofing sheet should be highly required. The professional processing of aluminum roofing sheet is the first key point to ensure long time using period. The classification of aluminum roofing sheet is mainly according to the surface treatment. The outer surface treatment of aluminium roofing sheet includes natural non-painted products and painted products.

1,Non-painted products: hammer-shaped aluminum sheet alloy (irregular pattern), embossed aluminum sheet alloy (through physical mechanical embossing to form regular pattern); pre-passivating anodized aluminum sheet. Such products are not painted on the surface, and the appearance requirement of the surface is not high and the price is low.

2, painting products: According to the coating process, it is divided into: spraying products and pre-roll coating. According to the type of paint, it can be divided into: polyester, polyurethane, polyamide, modified silicone, epoxy resin, fluorocarbon, etc., the purpose of painting on the surface of aluminum roofing sheet is to extend the aging of the paint against the ultraviolet rays of sunlight as long as possible, during the coated material, the PVDF (Fluorocarbon coating) has the best anti-aging properties, and it is the most powerful organic compound. The fluorocarbon coated aluminum roofing sheet is made of horizontal automatic two-coating two-bake, three-coating three-bake and four-coat four-bake roll coating processes according to different quality requirements. The pre-coated PVDF coating has a resin content of 70%-80%. It is coated on the high-speed continuous unit by chemical pretreatment, initial coating, fine coating, etc. The front coating is generally 25μm, and the anti-corrosive paint is applied back.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form