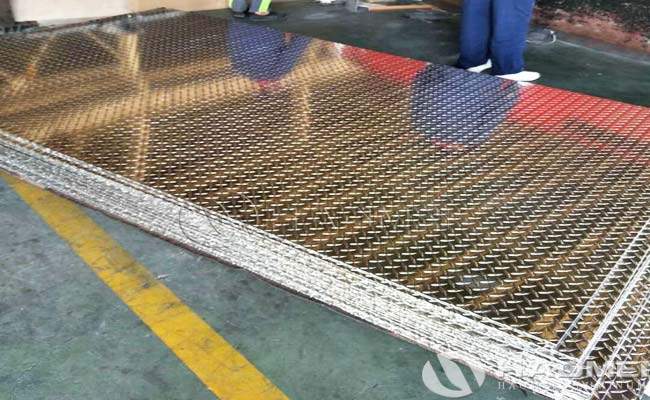

Diamond plate aluminum is a kind of aluminum checker tread plate, and it can also be called 1 bar aluminum plate. The alloy of diamond aluminum plate includes 1060 aluminum diamond plate, 5052 aluminum diamond plate, 3003 aluminum diamond plate and 6061 aluminum diamond plate. Diamond aluminum plate has good anti-slip properties. The effect is mainly used for the anti-skid of the carriage, the platform, the floor of the cold storage, the floor of the workshop, and the elevator.

The diamond plate aluminum is mainly non-slip aluminum plate, which is used for anti-skid on the ground, such as elevators, pedals, movable room floors, vehicles, ships and other industries. The aluminum diamond plate is processed by embossing and cutting. In high-speed cutting, due to the large machining allowance and discontinuous cutting, vibration often occurs during the milling process, which affects the machining accuracy and surface roughness of diamond aluminum plate. Therefore, the CNC high-speed machining process can generally be divided into: rough machining-semi-finishing-corner machining-finishing and other processes. For parts with high precision requirements, it is sometimes necessary to perform semi-finishing twice first, and then finishing. Parts after rough machining can be cooled naturally to eliminate internal stress caused by rough machining and reduce deformation. The margin left after rough machining should be greater than the deformation, generally 1 ~ 2mm. During finishing, the finished surface of the part should maintain a uniform machining allowance, generally 0.2 ~ 0.5mm is appropriate, so that the tool is in a stable state during the processing process, which can greatly reduce cutting deformation, obtain good surface processing quality, and ensure diamond plate aluminum product quality and accuracy.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form