Duct thermal insulation composite board is a specialized insulation material used in ventilation systems, which not only effectively reduces heat loss, but also improves the energy efficiency and comfort of the system. Orange peel embossed aluminum sheet for thermal composite boards has become one of the ideal surface materials for air duct insulation composite panels due to its unique surface texture and excellent performance.

Below is a detailed introduction to the features, structural composition, production process, application scenarios and advantages of orange peel embossed aluminum sheets for air duct thermal insulation composite panels.

Features of orange peel embossed aluminum sheet:

- Surface texture:

– The surface of orange peel embossed aluminum sheet shows a texture similar to orange peel, this special texture is not only beautiful, but also increases the three-dimensionality and hierarchy of the plate.

- Weather resistance:

– Aluminum itself has good corrosion resistance and weather resistance, after special treatment, orange peel embossed aluminum sheet in the humid and high temperature environment can still maintain a long service life.

- Wear resistance:

– The embossing treatment on the surface increases the wear resistance of the plate, making it not easy to be scratched and worn in long-term use.

- Easy to clean:

– Orange peel embossed aluminum sheet surface is smooth, not easy to accumulate dust, easy to clean and maintain.

- Decorative:

– Orange peel embossed aluminum sheet has a variety of colors and textures, which can be selected according to different architectural styles and design needs, enhancing the aesthetics of the air duct.

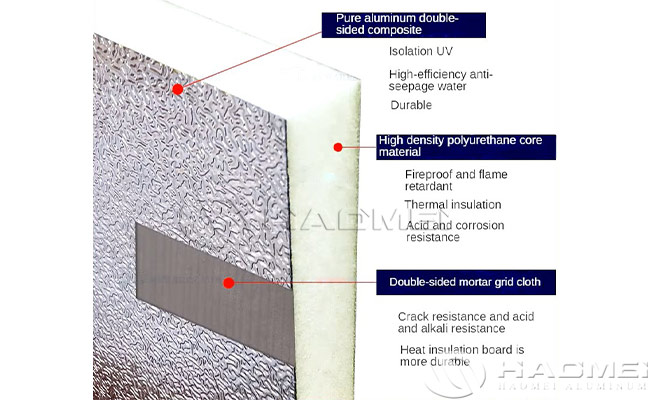

Structural composition of air duct insulation composite panel:

- Outer layer:

– Orange Peel Embossed Aluminum Sheet: provides beautiful surface and good protective performance.

- Middle layer:

– Insulation material: Commonly used insulation materials include polyurethane foam (PU), polystyrene foam (EPS), phenolic foam and so on. These materials have good thermal insulation performance and lightweight characteristics.

- Inner layer:

– Substrate: usually aluminum foil or aluminum sheet, providing good thermal conductivity and moisture resistance.

Production process of embossed aluminum sheet for thermal insulation composite boards:

- Substrate preparation:

– Select suitable substrate material, such as aluminum foil or aluminum sheet, and make sure its surface is flat and free of impurities.

- Insulation material pasting:

– Paste the insulation material on the substrate by special glue or mechanical fixing, make sure it is firmly and evenly pasted.

- Surface treatment:

– Fix the orange peel embossed aluminum sheet on the outer side of the thermal insulation material through roller pressing or other ways to ensure the surface is flat and free of bubbles.

- Quality testing:

– Carry out strict quality inspection on the finished products, including size, thickness, surface quality and thermal insulation performance, etc., to ensure that all the performance indexes of the products are in line with the standards.

Application scene of duct thermal insulation composite boards:

- Commercial buildings:

– In the ventilation system of shopping malls, office buildings, hotels and other large commercial buildings, the beauty and durability of orange peel embossed aluminum make them an ideal choice.

- industrial buildings:

– In the ventilation system of factories, warehouses and other industrial buildings, the corrosion and weather resistance of orange peel embossed aluminum make them suitable for use in harsh environments.

- Residential buildings:

– In the ventilation system of high-grade houses and villas, the decorative effect of orange peel embossed aluminum panels can enhance the quality of the living environment.

- public facilities:

– In the ventilation system of airports, stations, hospitals and other public facilities, the hygienic and easy-to-clean nature of the orange peel embossed aluminum sheet makes it suitable for use in high-traffic areas.

Advantages of thermal insulation composite boards for ducts:

- Excellent comprehensive performance:

– Duct insulation composite panel combines the aesthetics of orange peel embossed aluminum panels and the high efficiency of thermal insulation materials, with good comprehensive performance.

- Convenient construction:

– Duct insulation composite panel usually adopts modular design, easy and fast installation, greatly shortening the construction cycle.

- Energy saving and environmental protection:

– Efficient thermal insulation performance reduces energy loss, improves the energy efficiency of the system, in line with the development trend of green building.

- Health and safety:

– Orange peel embossed aluminum surface is smooth, not easy to breed bacteria and mold, suitable for use in places with high health requirements.

Orange peel embossed aluminum sheet as a high-performance surface decoration materials, and thermal insulation materials made of duct insulation composite panels have a wide range of prospects for application in the ventilation system. Its unique texture and beautiful appearance not only enhance the visual effect of the duct, but also provide excellent thermal insulation performance and durability.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form