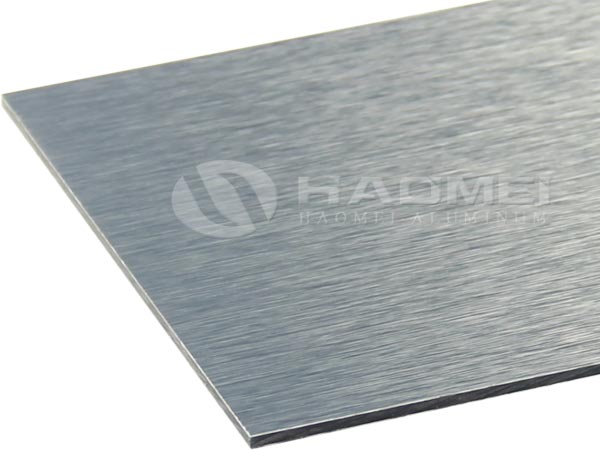

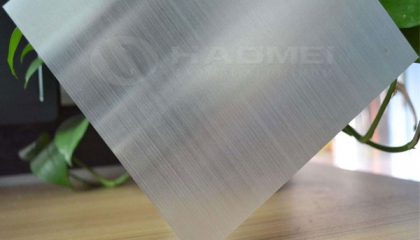

Brushed aluminum sheets 5052

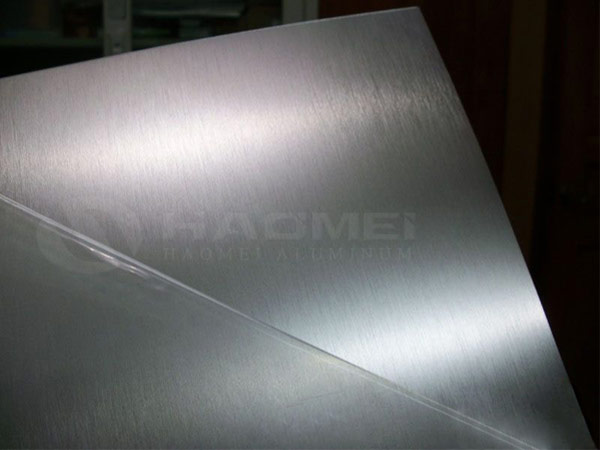

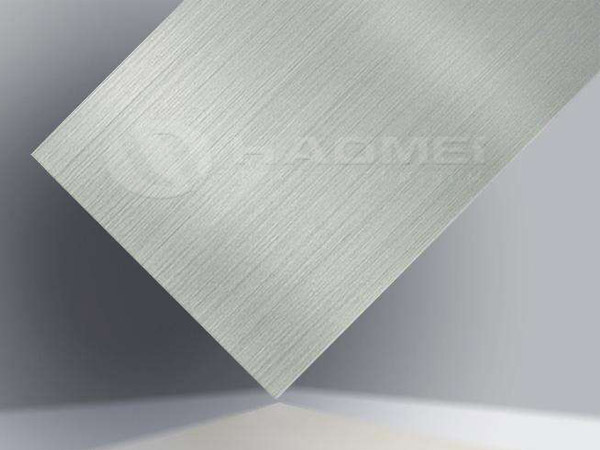

Brushed aluminum alloy 5052 is produced by using abrasive paper repeatedly to scrape lines on aluminum sheet. The main technological process can be divided into three pats: degrease, sander and washing. In the process of scraping lines of aluminum sheet, the special skin membrane technology after anodization can make the aluminum sheet surface generated a epithelial layer contained the metal elements, each tiny silk mark is visible, it makes the metal radiant fine-hair gloss.

Specification of brushed aluminum 5052:

Alloy: 5052

Temper: H14, H16, H18, H24, H32, H34

Thickness: 0.05mm-3.0mm

Width: 80-1600mm

Color: RAL Color, Silver, Golden, Bronze, Black, Pink, Red, green, stainless steel color

Brushed: Double side finished

Surface grain: straight grain, Nakanaga grain, short grain, cross pattern grain

Protection of surface: with film or not, according to your requirement

Packing Details: Strong timber pallet seaworthy packing according to ISPM 15

Application of 5052 aluminium brushed finish:

- Range hood and flue gas turbine

- Air-condition

- Water heater and calorifier

- Switch and on-off

- Electronic hardware

- Lamps and lanterns

- Aluminium composite panel

- Household and domestic appliances

- Mobile phone shell

- Aluminum frame

- Fine ambry

- Laminated board

- Sign and name plate

- Luggage,cases and suitcases

- Fire-proof plate

- Computer panel

- Car decoration panel

Features of brushed aluminum plate 5052:

- Super strong metallic, rich color, fashionable and upscale.

- Can be directly stamping forming, and the bending parts resistant to burst.

- Laundering durability, scratch resistant.

- Anti-static electricity, no aspiration, easy to clean.

- Used where corrosion resistance and good mechanical properties are primary requirements.

- It is easily formed and welded, and its matte finish is suitable for painting and plating.

- Abrasion resistance, non post-formable, stain resistance, water resistance

Pictures of brushed aluminium plate 5052:

Related Products

Brushed aluminum sheets

Brushed Aluminum Sheets are produced by using abrasive paper repeatedly to scrape lines on aluminum sheet. The main technological process can be divided into three pats: degrease, sander and washing.

Brushed aluminum sheets 1100

Alloy: 1100Temper: H14, H16, H18, H24, H32, H34

Thickness: 0.05mm-3.0mm

Width: 80-1600mm

Brushed aluminum sheets 3003

Alloy: 3003Temper: H14, H16, H18, H24, H32, H34

Thickness: 0.05mm-3.0mm

Width: 80-1600mm

Brushed aluminum sheets 5052

Alloy: 5052Temper: H14, H16, H18, H24, H32, H34

Thickness: 0.05mm-3.0mm

Width: 80-1600mm

Haomei Aluminum Sheet Plate

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form