Aluminum plate is widely used in many fields such as construction, transportation, and aviation due to its light weight, corrosion resistance, and ease of processing.

Here are a few common types of aluminum plates:

- Aluminum Alloy Plate:

– 1000 series: pure aluminum plate, containing more than 99% aluminum, with excellent corrosion resistance and electrical conductivity, commonly used in the chemical and electric power industries.

– 2000 series: the main alloying element is copper, with high strength, commonly used in aerospace, but poor corrosion resistance.

– 3000 series: the main alloying element is manganese, with good formability and corrosion resistance, commonly used in packaging materials for the food and chemical industries.

– 4000 Series: The main alloying element is silicon, which has good weldability and is commonly used in automotive and machinery manufacturing.

– 5000 series: the main alloying element is magnesium, with good corrosion resistance and weldability, widely used in ships, automobiles and construction industry.

– 6000 series: the main alloying elements are magnesium and silicon, with good workability and weldability, widely used in construction and structural materials.

– 7000 Series: The main alloying element is zinc, which has very high strength and is commonly used in aerospace and military applications.

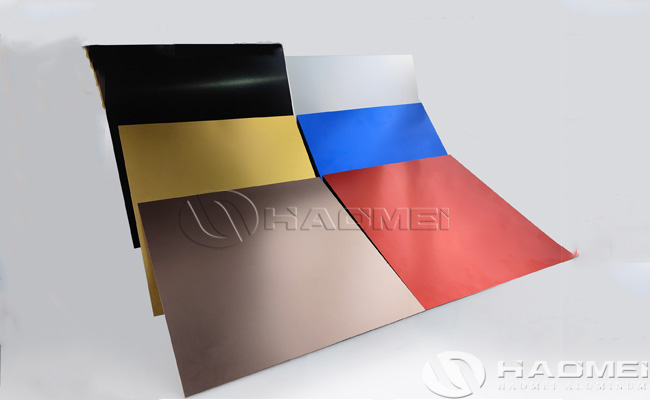

- Coated Aluminum Sheet:

This type of aluminum plate is coated with polyester or fluorocarbon coating, which has excellent corrosion resistance and decorative properties, and is commonly used for building facades, ceilings and billboards.

- Anodized Aluminum Plate:

Aluminum plate is placed in the corresponding electrolyte (e.g., sulfuric acid, chromic acid, oxalic acid, etc.) as the anode, and formed by electrolysis under specific conditions and applied current. The anode of the aluminum plate oxidation, the formation of a thin layer of aluminum oxide on the surface, the thickness of which is 5-20 microns, hard anodic oxide film up to 60-200 microns.

- Aluminum mirror plate:

The surface is highly polished with mirror effect, commonly used in decoration and art design.

- Aluminum CheckerPlate:

The surface has a patterned or concave-convex design to increase the anti-slip property, commonly used on floors, stairs and truck compartments.

- Aluminum Casting Plate:

Cast from aluminum alloy, with good strength and wear resistance, commonly used in mechanical parts and structural components.

These are some common types of aluminum plate, each type has its specific application areas and performance characteristics. According to the specific needs, you can choose the right aluminum plate material.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form