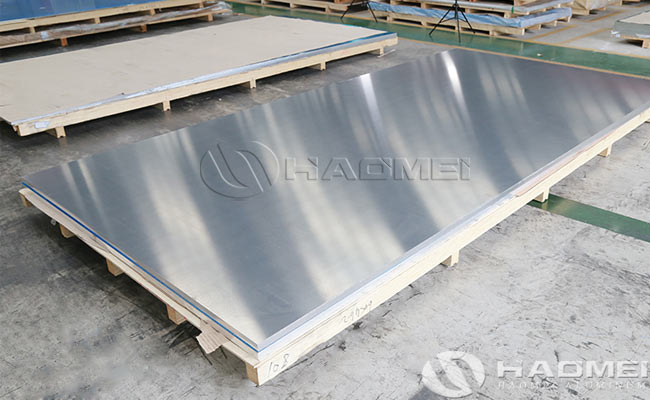

As an important metal material in today’s industrial and architectural fields, aluminum sheet has attracted much attention due to its unique physical properties and wide range of application scenarios. As the name suggests, aluminum sheet is a rectangular sheet made from aluminum ingots that have been rolled and processed. It is produced in a wide range of thicknesses, from 0.2mm thin to over 200mm thick. Aluminum sheets are widely used in a variety of fields because they not only have good electrical and thermal conductivity and corrosion resistance, but are also lightweight and easy to process.

There are many types of aluminum sheet, they have diverse classification and wide range of applications.

- Classification by alloy composition

– Pure aluminum sheet: rolled from pure aluminum, impurity content is very low. Pure aluminum sheet 1000 series has good electrical conductivity, thermal conductivity and plasticity, but the strength is low, suitable for occasions that do not require high strength.

– Alloy aluminum sheet: A certain proportion of alloying elements (such as copper, magnesium, silicon, zinc, etc.) are added on the basis of pure aluminum to improve its mechanical properties and corrosion resistance. Common aluminum alloy sheets include 2024, 3003, 5052, 6061, 7075 and other grades, which are widely used in aviation, automotive, shipping and other fields.

Aluminum-manganese alloy sheet: add appropriate amount of manganese to improve corrosion resistance, suitable for oil tanks, oil pipes and other liquid containers.

Aluminum-magnesium alloy sheet: adding magnesium to improve mechanical properties and corrosion resistance, commonly used in aircraft fuel tanks, transportation vehicles sheet metal parts.

Aluminum-zinc alloy sheet: zinc element is added to improve strength and corrosion resistance, applicable to building curtain walls, roofs and other occasions requiring high strength and corrosion resistance.

- Classification by thickness

– Thin aluminum sheet: thickness between 0.15-2.0mm, mainly used in packaging, printing, electronics and other fields.

– Regular aluminum sheet: thickness between 2.0-6.0mm, suitable for general industrial applications.

– Medium aluminum sheet: thickness between 6.0-25.0mm, commonly used in construction, machinery and other fields.

– Thick aluminum sheet: thickness between 25-200mm, even more than 200mm ultra-thick plate, mainly used for large structural parts and special demand occasions.

- Classification according to surface treatment

Anodic oxidation: forming a dense oxide film on the surface of aluminum sheet through electrolysis to improve corrosion resistance and aesthetics.

Spraying: One or more layers of coating (e.g. polyester, fluorocarbon, acrylic, etc.) are applied on the surface of aluminum sheet to increase the decorative and functionality.

Electroplating: Plating a layer of metal on the surface of aluminum sheet to improve electrical and thermal conductivity.

- Application Areas

Types of aluminum sheets are widely used in various fields due to their excellent performance:

– Architectural field: used in indoor and outdoor decoration, curtain wall, ceiling, etc. It is not only beautiful and generous, but also has good thermal insulation properties.

– Industrial field: in the electronics, machinery and other industries, aluminum sheet is used to manufacture a variety of components, parts and equipment.

– Transportation: the bodies and parts of automobiles, trains, airplanes and other means of transportation are often made of aluminum sheet to reduce weight and improve fuel efficiency.

– Other fields: aluminum sheet is also used in packaging, printing, electricity and many other industries, playing an irreplaceable role.

To sum up, types of aluminum sheet have become an indispensable and important material for modern industry and construction with its diverse types and wide range of applications. With the continuous progress of science and technology and the continuous expansion of the market, the application prospect of aluminum sheet will be even broader. We hope that this article can help readers understand the various classifications and characteristics of aluminum sheet more deeply, and provide reference and reference for practitioners and enthusiasts in related fields.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form